It’s a familiar, gut-wrenching sound: the high-pitched squeal, a sudden shudder, and then, silence. Your high-value production line or critical lab instrument has ground to a halt. After a frustrating teardown, you find the culprit: a tiny, shredded plastic or metal spacer. A component that costs pennies has just caused thousands of dollars in downtime.

Sound familiar? You're not alone.

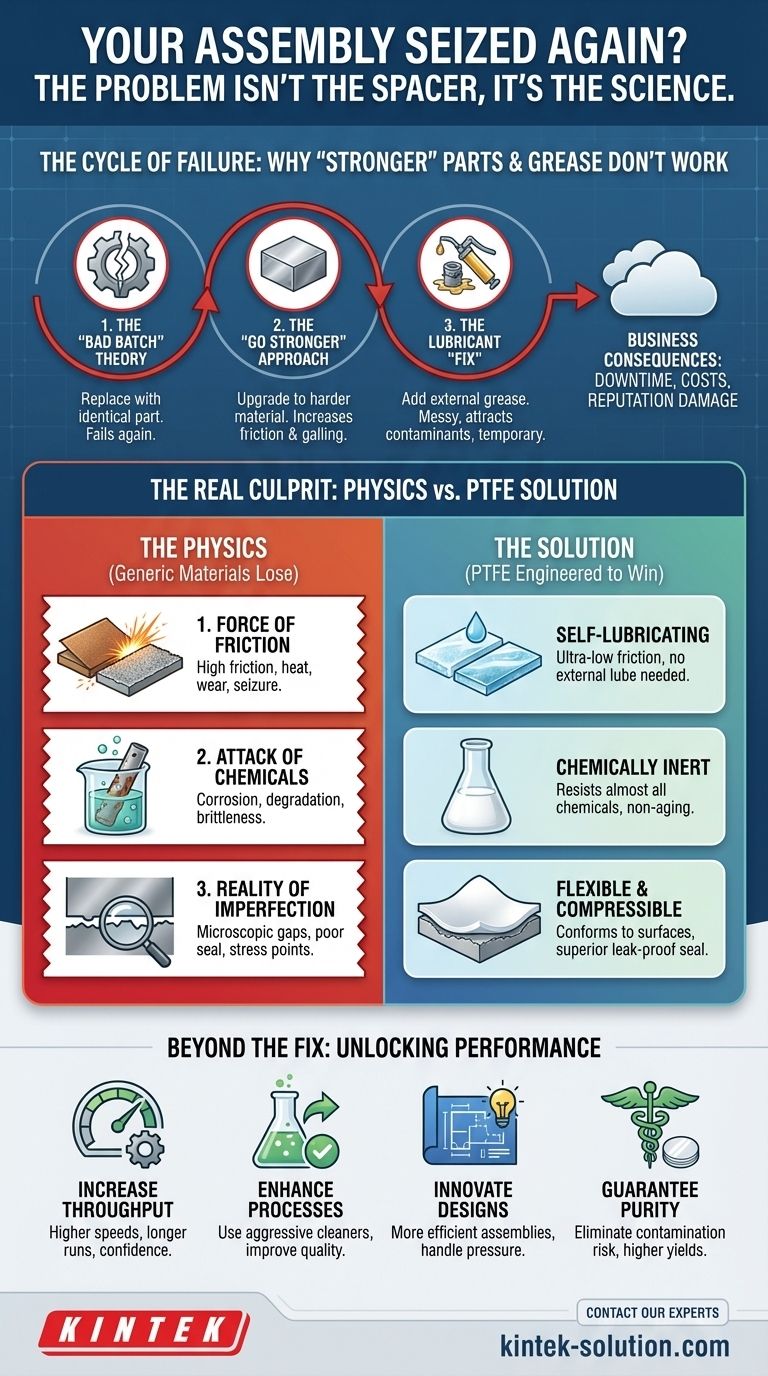

The Cycle of Failure: Why "Stronger" Parts and More Grease Don't Work

When a spacer fails, the reaction is predictable. Engineers and maintenance teams typically fall into a frustrating loop of trial and error:

- The "Bad Batch" Theory: You replace the failed spacer with an identical one, assuming the first was a fluke. It works for a while, and then it fails again in exactly the same way.

- The "Go Stronger" Approach: You decide the original material was too weak. You upgrade to a harder plastic or even a stainless steel spacer, believing hardness equals durability. To your surprise, the new spacer causes even more friction, galling, or catastrophic seizure of the moving parts.

- The Lubricant "Fix": You stick with the original part but slather the assembly in high-performance grease. This works temporarily, but it's messy, attracts contaminants, and requires constant re-application. In sensitive environments like semiconductor or medical manufacturing, this added lubricant is a non-starter.

Each of these "solutions" costs time and money. The business consequences are severe: unplanned downtime, missed production targets, costly maintenance cycles, and—worst of all—a compromised product that could fail in the field, damaging your company's reputation.

The reason this cycle repeats is that these fixes are all aimed at the wrong problem. You're treating the symptom, not the disease.

The Real Culprit: It's Not the Part, It's the Physics

The fundamental mistake is thinking of a spacer as a simple, static object. In reality, especially in a dynamic or chemically active environment, it's an active component. Its success or failure is not determined by its shape or simple hardness, but by its underlying material science.

Three invisible forces are at work, and generic materials are losing the battle on all fronts.

1. The Force of Friction

Imagine sliding two pieces of sandpaper together—that’s high friction. Now, imagine two blocks of wet ice—that’s low friction. Most materials, including steel and hard plastics, are like sandpaper at a microscopic level. Without a constant film of lubricant, they generate immense friction and heat when moving against another surface, leading to wear and seizure.

2. The Attack of Chemicals

Plastics become brittle and metals corrode when exposed to acids, solvents, or aggressive cleaning agents. A standard spacer may fit perfectly on day one, but over time, its material degrades, losing structural integrity until it cracks and fails, often leading to dangerous leaks.

3. The Reality of Imperfection

No machined surface is perfectly flat. Under a microscope, it’s a landscape of peaks and valleys. A rigid metal or hard plastic spacer can't conform to these microscopic imperfections. This creates tiny gaps, preventing a perfect seal and creating stress points where wear and corrosion can begin.

The "common fixes" fail because they ignore these root causes. A steel spacer increases friction. Another generic plastic part will just degrade again. External lubricant is a temporary patch for a material that fundamentally isn't suited for the job.

The Right Tool for the Job: How PTFE Is Engineered to Win

To permanently solve these issues, you don't need a "stronger" spacer. You need a spacer made from a material specifically engineered to master friction, resist chemicals, and conform to imperfect surfaces.

That material is Polytetrafluoroethylene (PTFE).

PTFE isn't just another plastic; it's a high-performance fluoropolymer designed for the most demanding applications. Its properties directly counter the root causes of spacer failure:

- It's Naturally Self-Lubricating: PTFE has one of the lowest coefficients of friction of any solid material on Earth—it’s the "wet ice" in our analogy. It creates an ultra-slick surface that minimizes wear and prevents seizure, without any external lubricant. This is why the common "go stronger" approach with metal often fails—it introduces more friction, not less.

- It's Nearly Chemically Inert: PTFE is exceptionally resistant to almost all industrial chemicals and solvents. It doesn't corrode, degrade, or become brittle. This "non-aging" quality ensures it maintains its integrity and sealing capability for years, even in the most corrosive environments where metals and other plastics would disintegrate.

- It's Flexible and Compressible: Unlike a rigid metal part, PTFE has a unique flexibility. It conforms to the microscopic peaks and valleys of mating surfaces, creating a superior, leak-proof seal where rigid parts would fail.

A PTFE spacer isn't just a part; it's a purpose-built engineering solution. Its smooth, waxy feel isn't a cosmetic feature—it's the physical evidence of its incredibly low-friction molecular structure.

Precision Matters: Turning a Material into a Solution

Having the right material is only half the battle. In semiconductor, medical, and high-tech industrial applications, "close enough" is not good enough. KINTEK specializes in transforming raw PTFE into precision-fabricated components. We understand that the performance of your multi-million dollar system can depend on the sub-millimeter tolerance of a single seal or spacer. We engineer our components not just to fit, but to perform flawlessly within the physical and chemical demands of your specific application.

Beyond the Fix: From Preventing Failure to Unlocking Performance

Once you replace the cycle of failure with a reliable PTFE solution, something powerful happens. You stop thinking about preventing downtime and start asking, "What's possible now?"

Resolving this persistent weak point frees your engineering and R&D teams to push the boundaries of what your systems can do:

- Increase Throughput: Run your machinery at higher speeds or for longer continuous periods with confidence, knowing that friction and wear are no longer limiting factors.

- Enhance Processes: Use more aggressive cleaning agents or operate in harsher chemical environments to improve your product's quality, without fear of component degradation.

- Innovate Designs: Engineer more compact, efficient, and ambitious assemblies, knowing you have a sealing and spacing solution that can handle the pressure.

- Guarantee Purity: In medical or semiconductor applications, eliminate the risk of contamination from lubricants or degraded part materials, ensuring higher yields and product safety.

Solving a persistent wear or sealing issue isn't just a technical victory; it's a strategic advantage that unlocks reliability, performance, and innovation. If you are tired of fighting the same battles with failing components, it's time to change the fight itself. Let's discuss how precision-engineered PTFE can solve your most persistent engineering challenges. Contact Our Experts

ビジュアルガイド

関連製品

- テフロン容器およびコンポーネントのためのカスタムPTFE部品メーカー

- テフロン部品とPTFEピンセットのためのカスタムPTFE部品メーカー

- PTFE化学溶剤サンプリングスプーン

- 先端科学・産業用途向けカスタムPTFE測定シリンダー

- 高度な産業用途向けのカスタムPTFEテフロンボール